Prototyping

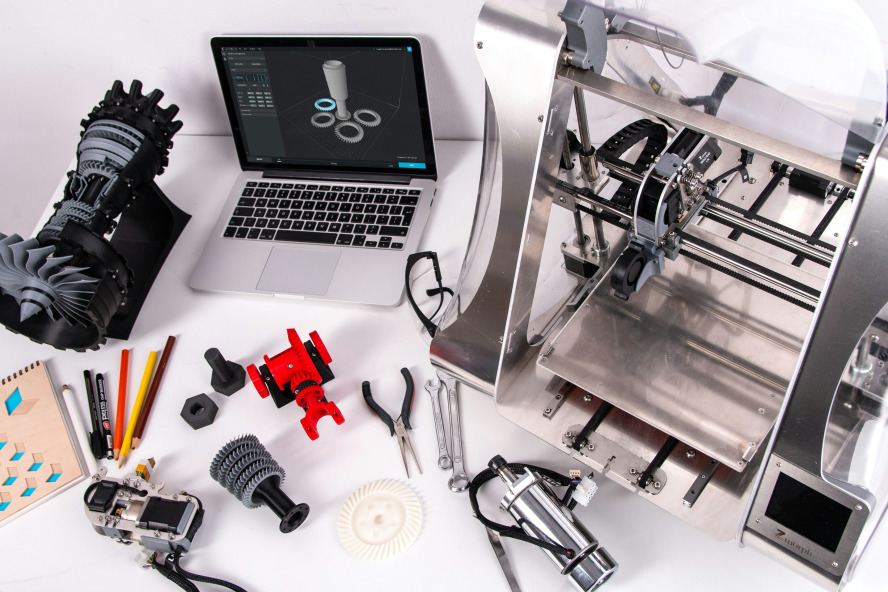

The prototyping process is an essential phase in product development that brings theoretical designs into the physical world. Once the detailed design is complete, prototypes are created to emulate production components and assemblies. This hands-on phase allows designers and engineers to visualize the product in a tangible form, providing invaluable insights into its real-world application. Prototyping involves various manufacturing techniques, such as machining, 3D printing, and short-run injection molding, to produce functional models. These prototypes undergo rigorous testing in both lab and real-world environments to evaluate their performance, durability, and usability, ensuring that the design meets all intended requirements and identifies any necessary adjustments before mass production.

By partnering with an us for prototyping, you gain access to specialized skills and resources that enhance the product development process. We manage the entire prototyping phase, from selecting the appropriate manufacturing methods to conducting comprehensive tests on the prototypes. We provide detailed feedback and analysis, pinpointing potential design flaws and areas for improvement. This iterative process of prototyping and testing enables the refinement of the design, ensuring that the final product is optimized for performance and manufacturability. Ultimately, our prototyping services facilitate a smoother transition from design to production, reducing risks and accelerating the time-to-market for new products.

In-House Capabilities

- Mechanical & Electrical Assembly: Complete assembly services for functional prototypes and products including ESD safe electronics and PCB assembly, wiring, and harnessing.

- CNC Machining: Precision machining on our vertical milling center.

- Turning and Precision Surface Grinding: High precision manufacturing for tooling grade machined components using our engine lathe and surface grinder.

-

Additive Manufacturing: Industrial grade rapid FDM/FFF manufacturing with 25+ materials including carbon filled nylon, polycarbonate, and conductive ABS.

-

Casting and Molding: Open-pour and manual injection molding of urethanes, silicones, resins, and low-temp metals. Including mold design and manufacturing

-

Composite Layup: Composite layup and resin infusion with fiberglass, carbon fiber, and Kevlar materials. Including composite mold design and manufacturing.

-

Laser Cutting and Engraving: Cutting, engraving and marking using our gantry style laser diode machine.

-

Performance Testing: Reliability, Durability and functionality testing, including automated cycle testing and monitoring, structural abuse load testing, and field testing.

-

QA Inspection: Rigorous quality control to ISO9001 and AS9100 best practices.

Integrated Prototyping & Engineering

Our multidisciplinary team works collaboratively to streamline the development process:

- Solid Modeling & CAD: Detailed 3D models for accurate visualization and planning.

- Finite Element Analysis (FEA): Structural analysis to predict product behavior under various conditions.

- Design for Manufacturing & Assembly (DFMA): Strategies to simplify production and reduce costs.

-

Design to Cost: We work backward from target pricing to engineer parts and assemblies that balance performance, quality, and cost.

-

Failure Modes & Effects Analysis (FMEA): Structured risk assessment to identify potential failure points early in development and mitigate them through robust design solutions.

-

2D Drafting & Detailed Drawings: Fully dimensioned mechanical drawings, GD&T, and callouts for accurate fabrication, inspection, and communication with suppliers.

-

Model-Based Definition (MBD): We support MBD workflows, embedding PMI (Product Manufacturing Information) directly into 3D CAD models to reduce reliance on 2D drawings and support digital manufacturing.

-

Reverse Engineering: We can recreate CAD geometry from physical samples or scan data, enabling part replication, design improvements, or digital archiving.

-

Rapid Concept Iteration: Quick-turn design studies to evaluate trade-offs, experiment with configurations, and converge on optimal solutions.

Market Research

Every great product starts with great research. It's critical to understand what the market needs, and what the competition is providing.

Concept Product Design

Through technology brainstorming, ideation and decision matrices, you'll receive a hashed out concept ready for detailed design.

Detailed Product Design

Get production ready engineering models and drawings ready to send to your suppliers for prototype or production.

Prototyping

Nothing beats the feeling of holding your product in your hand for the first time and seeing how well your product performs.

Supplier Development

Whether it's a local machine shop or overseas assembly, you'll have every connection you'll need to get quality parts on time and at a reasonable cost.

Production Planning

Build a lean and sustainable production process with a robust production plan.